Core Gameplay

For Alpha 4.4, the team supported the release of the Boomtube rocket launcher, resolved multiple weapon-related issues, and continued broader efforts to improve weapon handling. This included refinements to weapon feel, such as improved ADS control, and expanding the set of adjustable parameters available to designers.

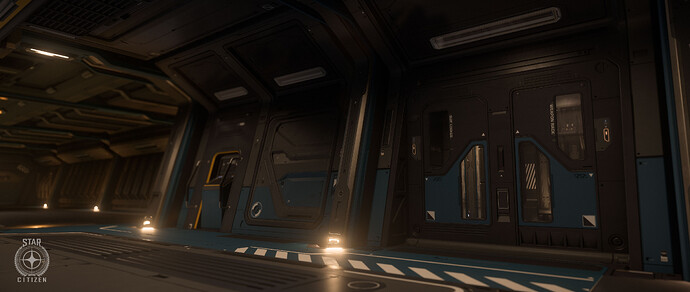

Engineering gameplay progressed through multiple Tech Preview releases before debuting in its first full iteration with Alpha 4.5, incorporating a wide range of changes driven by internal and community feedback. Updates included improved power-loss behavior, refined resource network logic, optional automatic Power Pip reassignment, and enhanced audio-visual feedback for ship emergencies.

Alpha 4.5 also introduced the initial implementation of Ship Armor and Life Support, adding greater depth and dynamism to multi-crew gameplay. In parallel, Core Gameplay and Player Experience teams reviewed critical feedback, resolving key issues for the release while scheduling others for future Engineering iterations.

During November and December, the team advanced the Crafting feature to Tech Preview readiness, enabling a limited round of Evocati testing. The initial preview focused on the core crafting loop, allowing item creation with stat variation based on material quality, alongside added support for material quality in shops and the ability to sell partially filled or mixed containers.

Further progress was made on the main Crafting UI, covering the production queue, delivery destination selection, material refunds, and the ability to dismantle crafted items. With the core functionality now in place, the team is preparing to review player feedback before refining and polishing the system ahead of its eventual release.

For flight gameplay, the team continued work on the improved Flight Model, refining control surfaces and exposing additional parameters to Design to better tune atmospheric flight behavior.

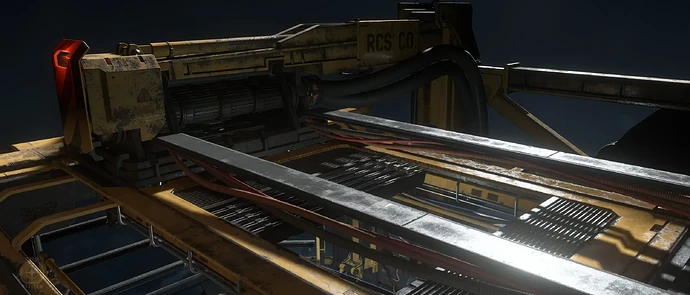

In parallel, development progressed on the Command Module used by the Drake Caterpillar and Ironclad. A first playable version was presented, demonstrating seamless control handover between the host ship and the Command Module, while also resolving several docking-related issues and improving debugging tools.

Toward the end of the year, the team focused on stabilizing the transit and freight elevator systems, prioritizing high-impact and persistent issues identified through player reports, QA, and Player Experience feedback, while acknowledging that further fixes are still ongoing.

Mission System updates introduced conditional mission completion, enabling alternative objectives in missions planned for Alpha 4.6, alongside fixes for courier drop-off lockers and support for new mission content and event tracking. Progress also continued on the Inventory Rework through internal testing, early groundwork was laid for capital-ship refueling, and Core Gameplay delivered a feature-complete cockpit light amplification (LAMP) system to improve visibility in low-light environments.

Economy

Based on community feedback, the Economy team rebalanced Wikelo’s rewards by reducing recipe requirements, redistributing certain items into the loot pool, and adding the Idris and Wolf.

The commodity price boost generated significant feedback, particularly around the improved profitability of previously undervalued free-trade resources, and these insights are already informing future balance changes. Contested zones also gained additional vehicle drops, while December efforts focused on developing the Nyx social station to support safe trading zones and economic incentives.

The devs are also looking into vehicle ballistic weapons to give them the proper caliber designations and operational costs associated with their size and type.